Pressure Transducter Piezoresistance Silicon Sensor

- Microcyber

- China

- In Stock

- 500 Sets/Month

Pressure Transducer: NCS-PT105IIS series pressure transmitter with advanced, mature, reliable piezoresistive silicon sensors has been designed meticulously by combining advanced microprocessor technology and digital capacitance measurement techniques, and it is available on FF Hl, PROFIBUS PA, PROFIBUS DP and HART protocols.

1. Support the latest versions of FF H1, PROFIBUS PA, PROFIBUS DP and HART protocols

2. Pressure types include gauge pressure, absolute pressure

3. High precision: ±0.075% SPAN

4. Long term stability: ±0.1% URL within 12 months

5. FCG FF interoperability test certification, PNO interoperability test certification (PA profile 3.02) and FCG HART interoperability test certification (HART 7),comply with DPV0 and DPV1 protocol

6. Explosion-proof (intrinsically safe, flameproof) certification

Pressure Transducter Piezoresistance Silicon Sensor

NCS-PT105IIS series Smart Pressure Transmitter with advanced, mature, reliable Piezoresistive Silicon Sensors has been designed meticulously by combining advanced microprocessor technology and digital capacitance measurement techniques. Its LCD can display many physical parameters such as pressure, temperature, current. It can be realized zero adjustment, range settings and other features by key-press operation, and easy to on-site tests.

NCS-PT105IIS series Smart Pressure Transmitter supports HART, FF H1, Profibus PA, Profibus DP protocol and can measure pressure, differential pressure, liquid level, flow, and other industrial parameters. It can be widely used in the petroleum, chemicals, electricity, and metallurgical industries, etc.

Piezoresistive Pressure Sensor Features

Excellent performance

-- Performance up to 0.075% of accuracy

-- Gauge pressure, absolute pressure

Flexibility

-- Automatically environmental temperature compensation

-- Parameters can be set by magnetic sticks, communicator, HOST software

Reliability

-- Measurement media: liquid, gas and stream

-- HART®, FOUNDATION™ Fieldbus, PROFIBUS®

-- Up to ±0.1% of Upper Range Limit (URL) for 1 year

Digital Pressure Sensor Details

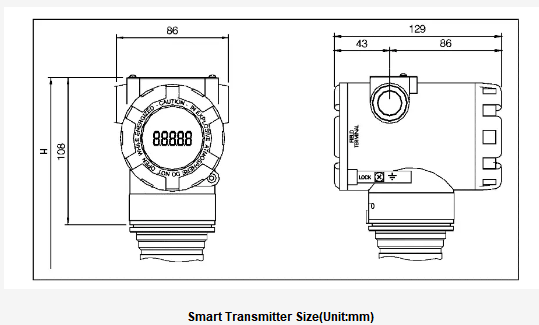

Pressure Indicator Transmitter Size

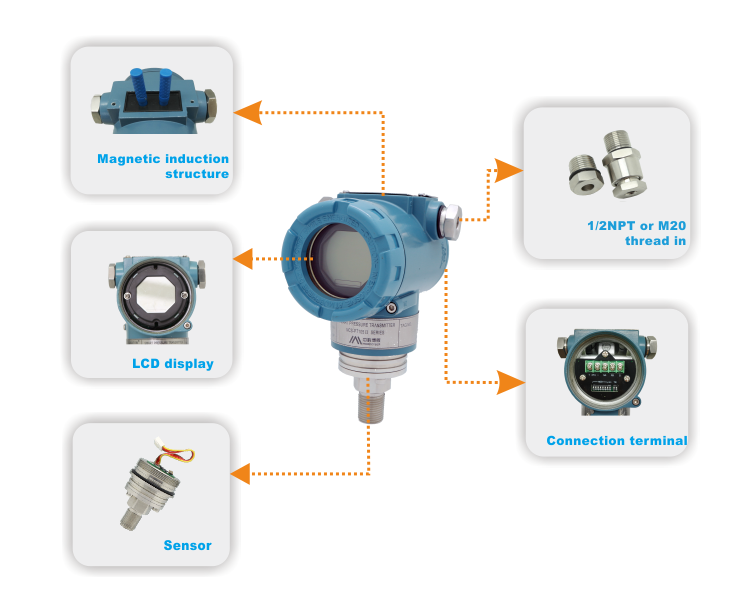

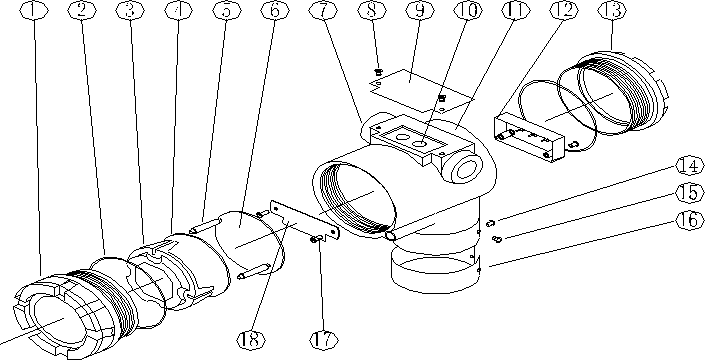

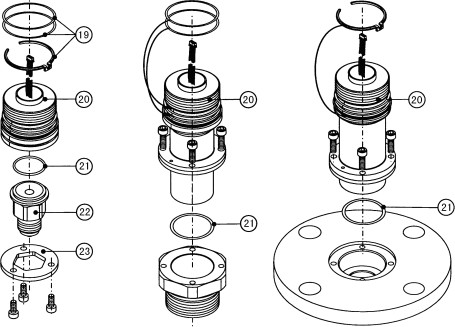

Components of Smart Transmitter are Shown in Picture:

The Exposed view and components of HART Smart Transmitter

1、Front cover

2、O-ring

3、LCD cover

4、Electronics/LCD

5、Post

6、Communication board

7、Wire hole

8、Screw

9、Name plate

10、Zero/span Adjustment hole

Insulation:

Voltage between terminal and housing:500Vrms (707VDC)

Display:

Optional 6 bits digital number or 5 bits characters LCD display

Temperature:

Work temperature:

-40 ~ 85℃ (without display)

-30 ~ 70℃ (with display)

-30 ~ 60℃(explosion-proof IC)

Store temperature:

-40 ~ 100℃ (without display)

-40 ~ 85℃ (with display)

Humidity scale:

5%~100%RH

Start time:

≤ 5 seconds

Refresh time:

0.2 seconds

Dump adjusting:

Constant of time 0~15 seconds

Performance specification

Precision:

±0.075% of the select range. If the select range <1/10 maximum of the range,

the precision is ±[0.025+0.005× (maximum range/select range)]% of select range

Temperature effect:

Effect of every change of 28℃ (50℉)

Select range ≥0.1 maximum range:±[0.019% of maximum range +0.125% of select range] ;

Select range <0.1 maximum range:±[0.025% of maximum range+0.125% of select range].

Long time stability:

In 12 months, ±0.1% of maximum range

Static pressure effect:

±0.25%/13.8MPa of maximum range

Location installed effect:

The maximum of the zero point movement is 0.24kPa

Power effect:

< 0.005%/V of range calibrated

Explosion-proof:

intrinsically safety Ex ia II C T4

Proof Level:

IP65

Vibration effect:

IEC 60068-2-6 Environmental testing - Part 2: Tests - Test Fc: Vibration (sinusoidal)

Electromagnetic compatibility:

IEC 61000-4-2 Electromagnetic compatibility (EMC)- Part 4-2: Testing and measurement techniques - Electrostatic discharge immunity test

IEC 61000-4-3 Electromagnetic compatibility (EMC) - Part 4-3 : Testing and measurement techniques - Radiated, radio-frequency, electromagnetic field immunity test

IEC 61000-4-4 Electromagnetic compatibility (EMC) - Part 4-4: Testing and measurement techniques - Electrical fast transient/burst immunity test

IEC 61000-4-6 Electromagnetic compatibility (EMC) - Part 4-6: Testing and measurement techniques - Immunity to conducted disturbances, induced by radio-frequency fields

IEC 61000-4-8 Electromagnetic compatibility (EMC) - Part 4-8: Testing and measurement techniques - Power frequency magnetic field immunity test

Physical Specification

Electrical connection: 1/2-14 NTP Female

Weight: 1.6kg (with LCD)

1.0kg (without LCD)

FAQ

Q:What are the contents of the retool inspection of the intelligent transmitter?

A:The content of retuning inspection of intelligent transmitter includes two aspects: function check and pressure check.

Q:How does a pressure transmitter work?

A:It is based on 3151 capacitive pressure sensor, using advanced microcontroller and sensorDigital measurement technology, the application of high accuracy algorithm, to ensure that the pressure signal of high precision measurement.wisdom

Q:What bus technology is used in the communication interface of intelligent transmitter?

A:The communication interface of intelligent transmitter is advanced HART, FF H1, PROFIBUS PA bus technology.

Q:How many parts does an intelligent transmitter consist of?

A:The intelligent transmitter has the same logical structure and is composed of five parts: sensor, instrument card, communication card, liquid crystal display card and terminal card.

Q: Can you provided OEM service?

A: Yes, we can, such as communication board, we can also provided fieldbus development toolkit.

Q: Can I get a free electronic manual?

A: Yes, if you want it, please contact us for Pressure Transducter Piezoresistance Silicon Sensor.

Hot Products