Foundation Fieldbus Development Toolkit For Electric Actuator Communication

- Microcyber

- China

- In Stock

- 500 Sets/Month

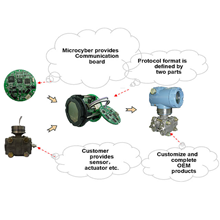

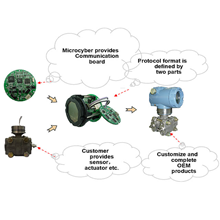

Foundation Fieldbus Development Toolkit For Electric Actuator Communication: Microcyber provides the Foundation fieldbus H1 communication board customized as customer's requirements. This solution can upgrade the traditional instrument to Foundation fieldbus instrument rapidly. The board supports bus communication, control and integration in fieldbus controller, stack, function block and interface circuit. Microcyber can assist customer in passing certification test of Foundation fieldbus and integration test with all kind of DCS system.Foundation Fieldbus Development Toolkit For Electric Actuator Communication

OEM Service Package -- FF Communication Board :

Software & Firmware Design and Development is including:

Hardware:

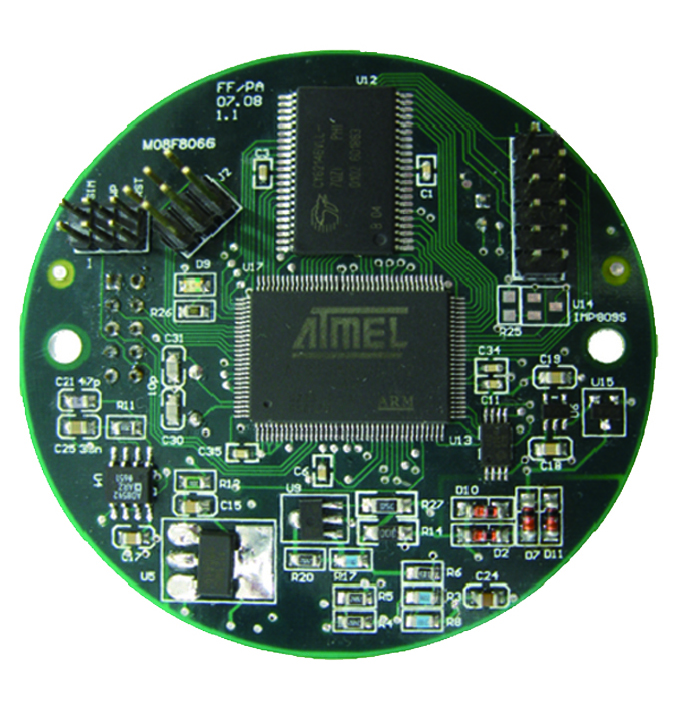

Support Atmel ARM7 series CPU

Discrete MAU

Flash ≥256K

RAM ≥128K

Support Link Master

Support EEROM for data store

Support asynchrony serial interface, baud rate is changeable

Support common I/O port

Power supplier: 9~32 VDC

Supply power to customer board according to customer's demand

Current consumption: ≤ 15mA

Supply to customer HW: 3V, 10mA or 5V, 6mA

Support two kind of communication controller

Smar FB3050

Microcyber FBC0409

Intrinsically safety: HW has passed FISCO

EMC compliance

Software:

Support function block instantiation

Registered function blocks: AI, AO, DI,DO, RATIO, PID, BG, ISEL, SC, LLAG

Customized function blocks

Supply firmware

Support LAS functionality

DD version: compliant with last ITK version 5.1.0.

Capabilities File (CFF): compliant with last ITK version 5.1.0.

Technical Service:

Foundation fieldbus ITK Pre-Test:

Microcyber provides Foundation Fieldbus ITK Pre-Test environment. The FF Interoperability Test is done for the field device at Microcyber prior to the official Interoperability Test. Microcyber explains the results and helps to analyze the errors.

The success of the Foundation Fieldbus ITK Pre-Test shows the official FF Interoperability Test will be passed.

Main technical support:

Foundation Fieldbus expert guidance

Minimized certification period

Use of official test tools

Foundation fieldbus interoperability test support:

Microcyber provides customers technical support for the Foundation Fieldbus Interoperability Test (ITK) at the Fieldbus Foundation in Austin, USA. As part of completed services, Microcyber is supporting:

Foundation Fieldbus professional guidance

Request for test offer from Fieldbus Foundation

Test order at Fieldbus Foundation

Error analysis

Control system integration test support:

Microcyber is supporting customer during the performance of control system integration test with ABB, EMERSON, YAKOGAWA, etc.

General Conditions:

There is no a stack license fee.

There is no an annual support fee in first year. Microcyber will provide customer new revision if there are upgrades or modifications to firmware.

Customer should provide a product sample to be used by Microcyber for software development. Microcyber should have the product sample within three weeks after the software development agreement is signed.

Development Schedule Preview: 3 months per device type

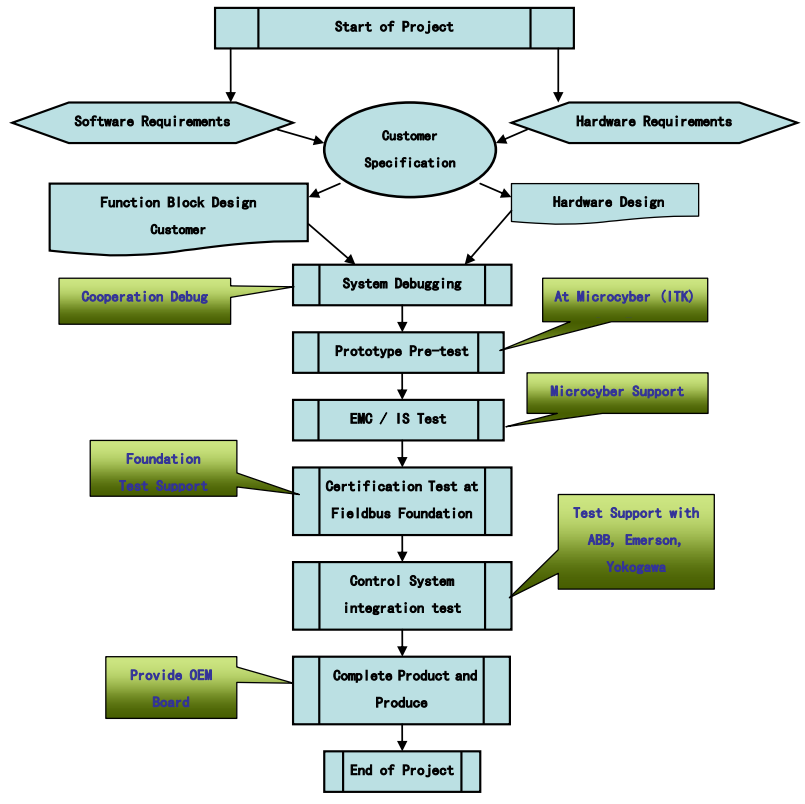

Development Procedure:

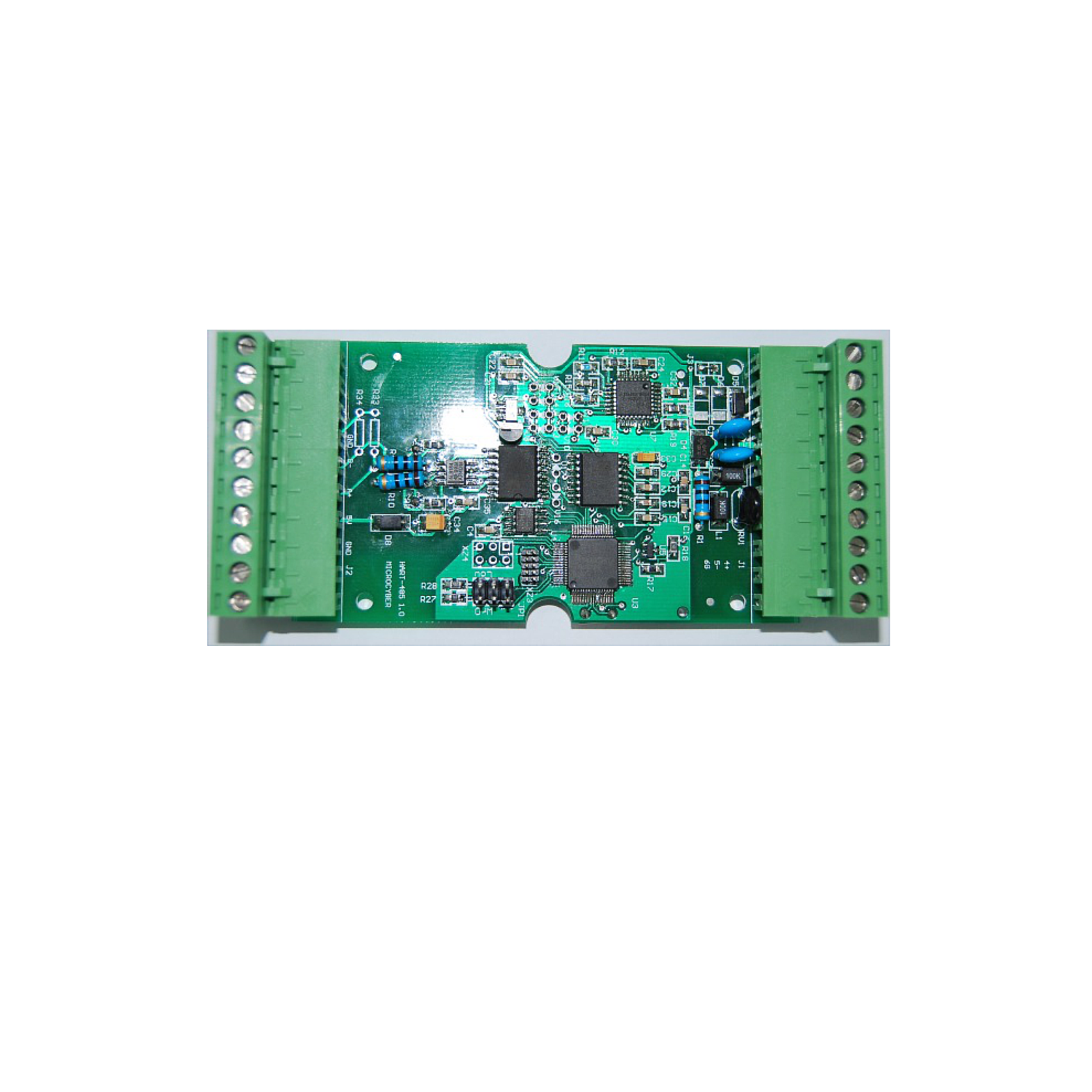

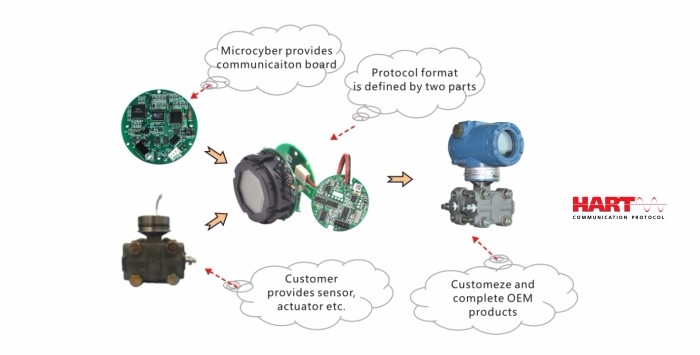

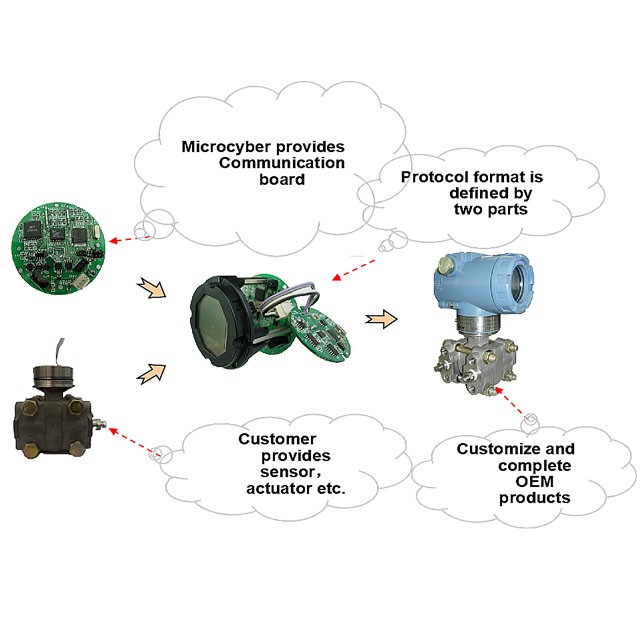

OEM Service Package -- HART Communication Board:

Microcyber provides the HART communication board customized as customer’s requirements. This solution can upgrade the traditional instrument to HART instrument rapidly. The board supports HART Universal Command, Common Practice Command and analog current output. Microcyber can assist customer in passing certification test of HART with the HCF test system.

Software & Firmware Design and Development is including:

Hardware:

Power supplier: 12~42 VDC

Operation temperature: - 40 ~ 85℃

Supply to customer board: 3.3V, 2.5mA or customer requirements

Support asynchrony serial interface, baud rate is changeable

Local adjustment

Support hardware failure alarm

Write-protect jumper

Display: 6 bits digital and 5 bits characters LCD display(optional)

Intrinsically safety: passed Explosion-proof certified of NEPSI

EMC compliance

Software:

Support HART 6.0 or 7.0

Provide configuration software

Support Burst Mode

Support all Universal Command:

Command Description:

0: READ UNIQUE IDENTIFIER

1: READ PRIMARY VARIABLE

2: READ P. V. CURRENT AND PERCENT OF RANGE

3: READ DYNAMIC VARIABLES AND P. V. CURRENT

6: WRITE POLLING ADDRESS

7: READ LOOP CONFIGURATION

8: READ DYNAMIC VARIABLE CLASSIFICATIONS

9: READ DEVICE VARIABLES WITH STATUS

11: READ UNIQUE IDENTIFIER ASSOCIATED WITH TAG

12: READ MESSAGE

13: READ TAG, DESCRIPTOR, DATE

14: READ PRIMARY VARIABLE SENSOR INFORMATION

15: READ PRIMARY VARIABLE OUTPUT INFORMATION

16: READ FINAL ASSEMBLY NUMBER

17: WRITE MESSAGE

18: WRITE TAG, DESCRIPTOR, DATE

19: WRITE FINAL ASSEMBLY NUMBER

20: READ LONG TAG

21: READ UNIQUE IDENTIFIER ASSOCIATED WITH LONG TAG

22: WRITE LONG TAG

38: RESET CONFIGURATION CHANGED FLAG

48: READ ADDITIONAL TRANSMITTER STATUS

Customized Special Command

DD version: compliant with last DD-IDE

Technical Service:

HART Device Registration Pre-Test:

Microcyber provides HART Device Registration Pre-Test environment. The HART Physical Layer Test, Slave Data Link Layer Test, Slave Universal Command Test and Slave Common Practice Command Test will be done at Microcyber.

The success of the HART Device Registration Pre-Test shows the official HART Device Registration Test will be passed.

Main technical support:

HART expert guidance

Minimized certification period

Use of official test tools

HART interoperability test support:

Microcyber provides customers technical support for the HART Device Registration Test at the HCF in Austin, USA. As part of completed services, Microcyber is supporting:

HART professional guidance

Request for test offer from HART

Test order at HART

Error analysis

General Conditions:

There is no an annual support fee in first year. Microcyber will provide customer new revision if there are upgrades or modifications to firmware.

Customer should provide a product sample to be used by Microcyber for software development. Microcyber should have the product sample within three weeks after the software development agreement is signed.

Development Schedule Preview: 3 months per device type

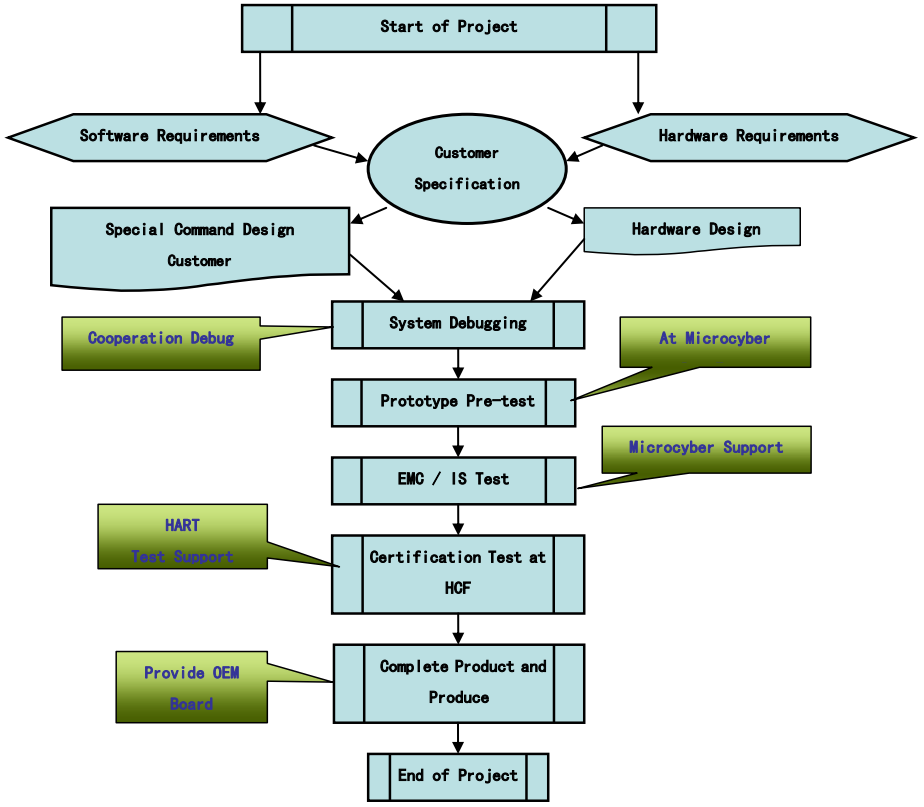

Development Procedure:

OEM Service Package -- PROFIBUS PA Communication Board:

Microcyber provides the PROFIBUS PA communication board customized as customer’s requirements. This solution can upgrade the traditional instrument to PROFIBUS PA instrument rapidly. The board supports bus communication, control and integration in fieldbus controller, stack, function block and interface circuit. Microcyber can assist customer in passing certification test of PNO and integration test with all kind of DCS system.

Software & Firmware Design and Development is including:

Hardware:

Support Atmel ARM7 series CPU

Discrete MAU

Flash ≥256K

RAM ≥128K

Support DPV0, DPV1 and PA Profile 3.01

Support EEROM for data store

Support asynchrony serial interface, baud rate is changeable

Support common I/O port

Power supplier: 9 ~ 32 VDC

Supply power to customer board according to customer’s demand

Current consumption: ≤ 15mA

Supply to customer HW: 3V, 10mA or 5V, 6mA

Support two kind of communication controller

Smar FB3050

Microcyber FBC0409

Intrinsically safety: HW has passed FISCO

EMC compliance

Software:

Support function block AI,AO,DI,DO and TOT

Customized transducer blocks

EDD File: compliant with SIMATIC PDM 6.0

Technical Service:

Certification Pre-Test:

Microcyber provides Certification Pre-Test environment. The Certification Test is done for the field device at Microcyber prior to the PNO official Certification Test. Microcyber explains the results and helps to analyze the errors.

The success of the Certification Pre-Test shows the PNO official Certification Test will be passed.

Main technical support:

PROFIBUS PA expert guidance

Minimized certification period

Use of official test tools

PNO Certification test support:

Microcyber provides customers technical support for the PNO Certification Test at the Test Lab in the world. As part of completed services, Microcyber is supporting:

PROFIBUS PA professional guidance

Request for test offer from Test Lab

Test order at Test Lab

Error analysis

General Conditions:

There is no a stack license fee.

There is no an annual support fee in first year. Microcyber will provide customer new revision if there are upgrades or modifications to firmware.

Customer should provide a product sample to be used by Microcyber for software development. Microcyber should have the product sample within three weeks after the software development agreement is signed.

Development Schedule Preview: 3 months per device type

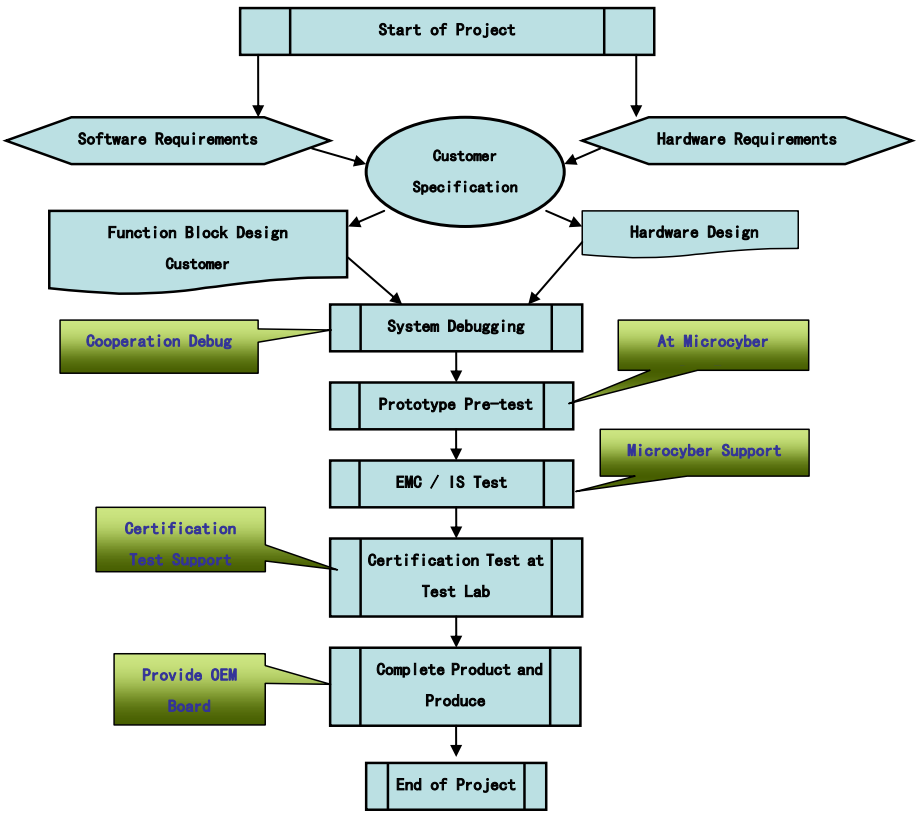

Development Procedure:

Hot Products--FF PA DP HART Communication Board :