What is Fieldbus?

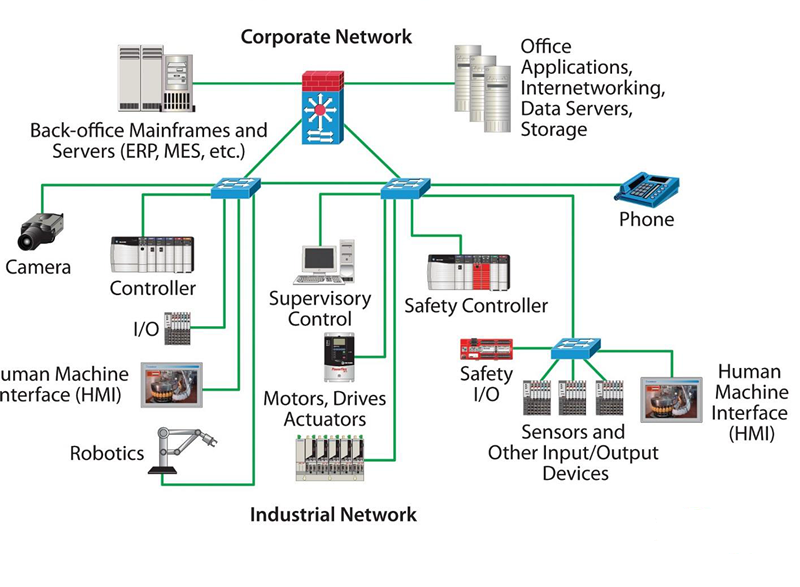

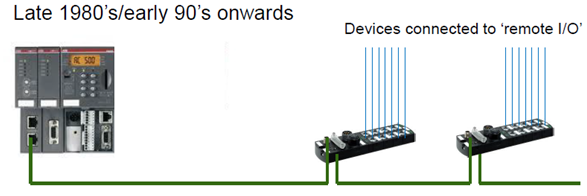

Fieldbus is simply a means of communicating with input devices (sensors, switches, etc.) and output devices (valves, drives, indication lamps etc.) without the need to connect each individual device back to the controller (PLC, Industrial PC etc.). Therefore, overall, Fieldbus can reduce costs.

Microcyber explain just what a Fieldbus is and also how Fieldbus control platforms work and perform.

Prior to its introduction, computers would connect using direct serial connections whereby only two devices could communicate per connection. The Fieldbus, on the other hand, allows hundreds of analogue and digital points to connect simultaneously. This reduces both the number of cables required, whilst also cutting down the length of the cable needed.

There are a number of different fieldbus variants available, including:

· AS-I Interface

· Ethercat

· Profinet

· Canopen

· Ethernet/IP

· Sercos Interface

· CC-Link

· Ethernet Powerlink

· Sercos the automation bus

· CompoNet

· Modbus

· SmartWire-DT

· DeviceNet

· IO-Link

· Ethernet

· Profibus

· Varan

There are so many Fieldbus variant solutions available because the manufacturers of automation equipment developed proprietary Fieldbuses with differing features and functions to best deal with their market niche and to compete with each other on a technical level. Therefore, not surprisingly, some buses are better at specific functions than others.

Due to market pressure, most Fieldbuses now claim to be ‘open’ (some more so than others). This is because large end companies wanted to be able to connect and use the installed control platform (e.g. PLC) to communicate via the Fieldbus to specialist devices from a range of different manufacturers to essentially ‘talk’ to the control platform.