The importance of temperature in remote sealed pressure transmitter

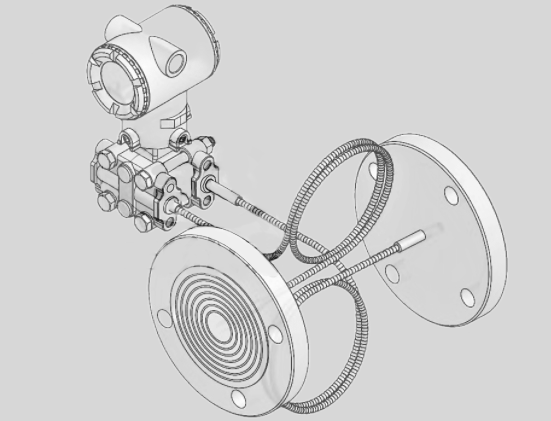

Why is temperature an important factor in pressure transmitters equipped with remote seals (sometimes called "chemical" seals)? Specifically, what temperature conditions may cause measurement errors in differential pressure meters with remote seals? In addition, please describe what happens to a pressure instrument equipped with a remote seal if a leak occurs in a capillary tube.

An increase in temperature will cause the filling liquid in the capillary tube to expand, thereby generating pressure on the sensor element of the transmitter, regardless of the pressure of the process fluid being measured. If the transmitter equipped with a seal is essentially impassable, and the temperature of the sealing unit and the capillary tube are equal, any pressure caused by the temperature will be offset at the transmitter, which will not be a problem.

However, if the temperature of one seal or capillary is higher than the temperature of another seal or capillary, the transmitter will detect and interpret the pressure difference caused by the temperature of the process fluid pressure difference.

The remote seal/capillary system must be completely free of gas (only liquid inside) to work properly. If even small cheongsam or other air bubbles enter the fluid between the distal sealing diaphragm and the sensing element, the fluid will be compressible, which means that the sealing diaphragm will shift more than the fluid diaphragm. fluid. The sensing element of the instrument. Therefore, the instrument may not be able to "see" the pressure change during the entire process exerted on the sealing diaphragm, and its measurement accuracy will be compromised.

In short, the leakage in the remote sealing system has a very detrimental effect on the accuracy of the instrument. If such a system leaks, the entire instrument must be replaced. Even if the leak can be repaired, the sealing device, the sealing device, the capillary tube and the pressure chamber of the transmitter must be "filled" with a new filling liquid under a strong vacuum to "pull out" the dissolved bubbles from the liquid. Needless to say, the equipment required for this kind of operation is usually not available in the factory instrument store, so you cannot repair the instrument.