The Fundamentals of Temperature Transmitters

Temperature measurement is a crucial aspect of many industrial processes, and accurate temperature monitoring is essential for maintaining efficiency, safety, and quality control. At the heart of these temperature measurement systems lies the temperature transmitter, a sophisticated device that converts temperature readings into electrical signals for easy transmission and integration into control systems. In this comprehensive guide, we'll explore the inner workings of temperature transmitters, with a special focus on the advanced NCS-TT105 Temperature Transmitter.

The Fundamentals of Temperature Transmitters

Temperature transmitters are indispensable components in process control and automation systems. These devices take temperature measurements from sensors and convert them into standardized output signals that can be easily interpreted by control systems or displayed on monitoring equipment. The primary function of a temperature transmitter is to amplify, linearize, and convert the sensor's signal into a format that can be transmitted over long distances without degradation.

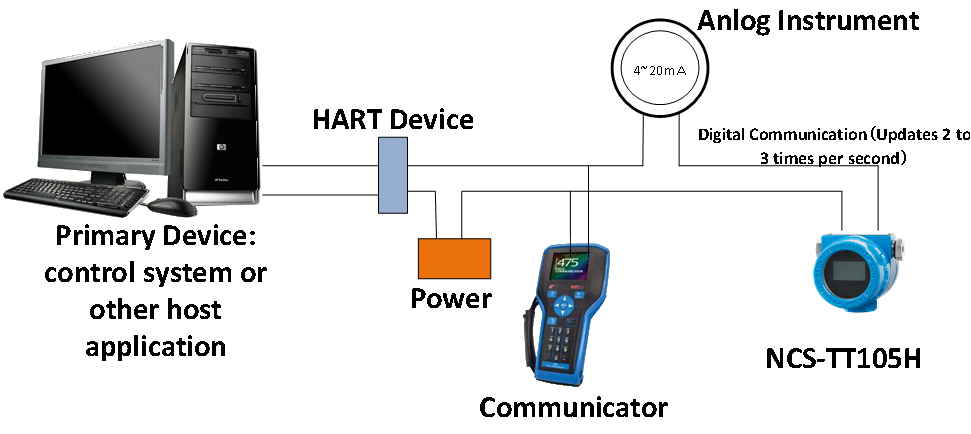

Modern temperature transmitters, like the NCS-TT105, utilize smart technology and fieldbus protocols to enhance their capabilities. These advanced features allow for improved accuracy, remote configuration, and seamless integration with digital control systems. The NCS-TT105 Temperature Transmitter, in particular, supports multiple industrial bus protocols such as HART, Foundation Fieldbus, and PROFIBUS PA, making it a versatile choice for various industrial applications.

The Inner Workings of a Temperature Transmitter

To understand how a temperature transmitter works, let's break down the process step by step:

1. Sensor Input: The temperature transmitter begins by receiving input from a temperature sensor. This sensor could be a thermocouple, resistance temperature detector (RTD), or thermistor. The NCS-TT105 Temperature Transmitter supports dual-channel sensor input, allowing for redundancy and hot backup capabilities.

2. Signal Conditioning: The raw signal from the sensor is typically weak and needs to be amplified and conditioned. The transmitter's internal circuitry amplifies the signal and filters out any noise or interference.

3. Linearization: Many temperature sensors have a non-linear response to temperature changes. The transmitter's microprocessor applies linearization algorithms to ensure the output accurately represents the actual temperature across the entire measurement range.

4. Cold Junction Compensation: For thermocouple inputs, the transmitter performs cold junction compensation to account for the temperature at the connection point. The NCS-TT105 boasts a cold end compensation accuracy of ± 1.0℃, ensuring highly precise measurements.

5. Analog-to-Digital Conversion: The conditioned and linearized signal is converted from analog to digital format by an analog-to-digital converter (ADC). This allows for further processing and communication using digital protocols.

6. Digital Processing: The digital signal is processed by the transmitter's microprocessor. This step may involve applying calibration factors, performing diagnostics, or implementing specific measurement algorithms.

7. Output Signal Generation: Based on the processed digital signal, the transmitter generates an output signal. This could be an analog current signal (typically 4-20mA) or a digital signal using protocols like HART, Foundation Fieldbus, or PROFIBUS PA.

8. Communication: The transmitter communicates the temperature data to the control system or monitoring device using the appropriate protocol. Advanced transmitters like the NCS-TT105 support multiple protocols, offering flexibility in system integration.