NCS-TT106 Head Mounted Temperature Transmitter

1.Overview

NCS-TT106F intelligent temperature transmitter adopts field bus technology, is a new generation of intelligent temperature transmitter, is an indispensable field device in process control. The device integrates a wealth of functional modules, which can achieve both general detection functions and complex control strategies.

NCS-TT106F adopts digital technology and can be applied to a variety of thermal resistance and thermocouple sensors. It has a wide measuring range and a simple interface between the field and the control room.

NCS-TT106F series intelligent temperature transmitter supports Foundation Fieldbus protocol, which can be widely used in petroleum, chemical, electric power, metallurgy and other industries.

2.Temperature transmitter installation

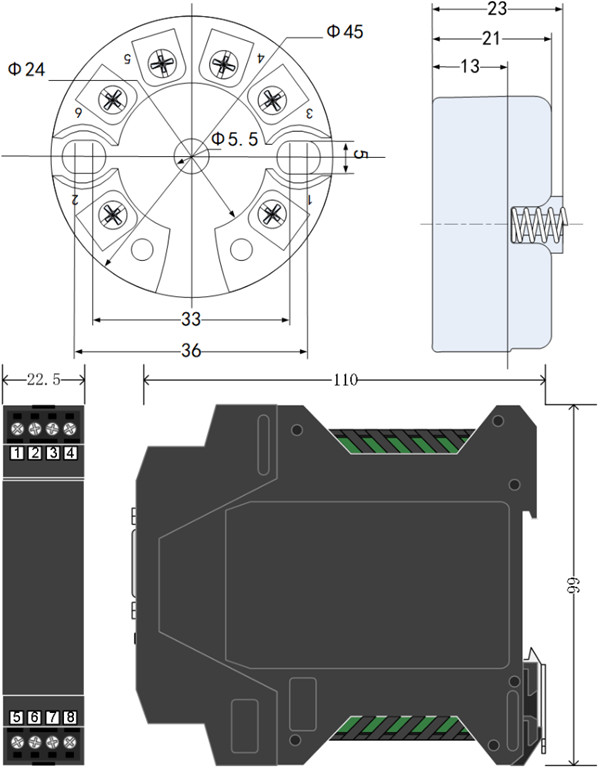

Dimensions

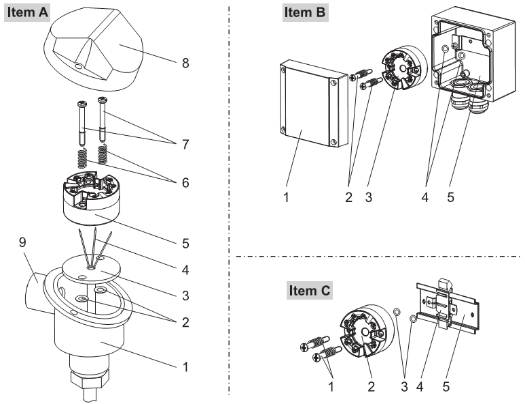

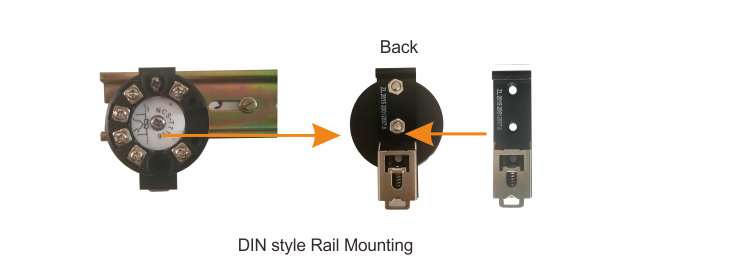

Installation

Via positioning hole, use two screws to install the temperature module to temperature housing or rail.

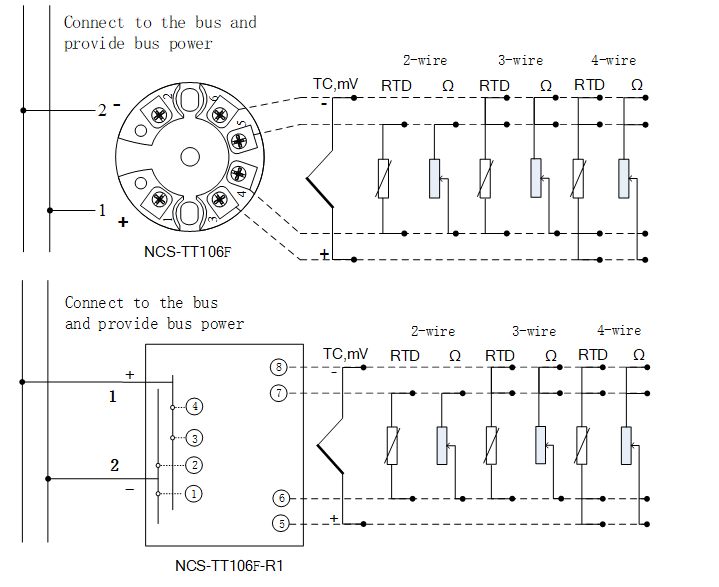

Wiring

The power supply of NCS-TT106F temperature transmitter and bus signal share a pair of cables, called bus cable. It is recommended to use the fieldbus dedicated cable recommended by IEC61158-2. The signal cable and bus cable should not share the conduit or open channel with the power cables of other equipment, and should be far away from high-power equipment. The shielded wires at both ends of the bus are grounded by single-ended grounding.

3.Technical specifications

Basic parameters

Bus interface | FOUNDATION FIELDBUS |

Bus power | 9~32VDC 9~17.5VDC(Intrinsically safe) |

Input signal | Pt100、Pt1000、CU50、CU100、0~500Ω、0~4000Ω resistance; B E J K N R S T thermocouple、-100mV~100mV、Custom defined TC、Custom defined RTD |

Number of channels | Single channel |

RTD wiring | 2-wire、3-wire、4-wire |

Update time | 0.5s |

Operating temperature | -40~85℃ |

Storage temperature | -40~85℃ |

Humidity range | 5~95%RH |

Electrical isolation | 1000VAC |

Voltage effect | ±0.005%/V |

Protection level | Terminal IP00 ;Housing IP40 |

Explosion-proof | Ex ia IIC T4 Ga |

EMC | GB/T 18268.1-2010 Immunity requirements for industrial sites in "Electromagnetic Compatibility Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use Part 1: General Requirements" GB/T 18268.25-2010 "Electromagnetic compatibility requirements for electrical equipment for measurement, control and laboratory use-Part 25: Special requirements. Test configuration, working conditions and performance criteria for field devices whose interfaces conform to IEC 61784-1, CP 3/2" |

Thermal resistance technical index

RTD Normal temperature accuracy index(25℃)

Signal type | Recommended range(℃) | Accuracy | Temperature drift (per ℃) |

Resistance signal | 0~500Ω | ±0.04Ω | ±0.001Ω |

0~ 4000Ω | ±0.35Ω | ±0.015Ω | |

PT100 | -200~850℃ | ±0.15℃ | ±0.003℃ |

PT1000 | -200~850℃ | ±0.15℃ | ±0.005℃ |

CU50 | -50~150℃ | ±0.15℃ | ±0.005℃ |

CU100 | -50~150℃ | ±0.10℃ | ±0.003℃ |

RTD Other technical indicators

Wiring | 2、3、4 |

Common mode rejection ratio | ≥70dB(50Hz & 60HZ) |

Differential mode rejection ratio | ≥70dB(50Hz & 60HZ) |

Thermocouple technical indicators

Thermocouple room temperature accuracy index(25℃)

Signal type | Range | Recommended range | Accuracy | Temperature drift (per ℃) |

mV | -100mV~+100mV | -100mV~+100mV | ±0.025mV | ±0.001 mV |

B | 0℃~1820℃ | 500℃~1810℃ | ±0.77℃ | ±0.050℃ |

E | -270℃~1000℃ | -200℃~1000℃ | ±0.20℃ | ±0.025℃ |

J | -210℃~1200℃ | -190℃~1200℃ | ±0.35℃ | ±0.01℃ |

K | -270℃~1372℃ | -200℃~1372℃ | ±0.40℃ | ±0.025℃ |

N | -270℃~1300℃ | -190℃~1300℃ | ±0.50℃ | ±0.015℃ |

R | -50℃~1768℃ | 0℃~1768℃ | ±0.75℃ | ±0.023℃ |

S | -50℃~1768℃ | 0℃~1768℃ | ±0.70℃ | ±0.023℃ |

T | -270℃~400℃ | -200℃~400℃ | ±0.35℃ | ±0.015℃ |

Other technical indicators of thermocouple

Compensation accuracy | ±0.5℃ |

Sensor type | B,E,J,N,K,R,S,T;-100mV~+100mV Voltage |

Common mode rejection ratio | ≥70dB(50Hz & 60HZ) |

Differential mode rejection ratio | ≥70dB(50Hz & 60HZ) |

Physical characteristics

Size | NCS-TT106F:¢45*23mm;NCS-TT106F-R1:110*99*22.5mm |

Housing material | Nylon |

Application

Microcyber is the member of FieldComm Group(FCG) and Profibus National Organization (PNO) .

Microcyber passes the Authentication of ISO 9001 Quality System, and has an outstanding innovative R&D team, plentiful practical experiences of design of the Automatic engineering, a leading product series, a huge market network, a strict quality management system and an excellent enterprise culture. All these further a solid foundation of entrepreneurship and sustainable development for Microcyber.

Carrying the ideals of employees, creating customer value and promoting enterprise development.