Application of Differential Pressure Transmitter

Application of Differential Pressure Transmitter

Basic situation

The electrolytic repolarization cell is the first forced circulation ionic membrane electrolysis device put into operation in a factory, with a designed annual output of 2x10⁴t caustic soda. The main equipment is two MBC ion membrane electrolyzers, the working medium is: brine, magnetism, chlorine, hydrogen. The device was put into use in January 2008.

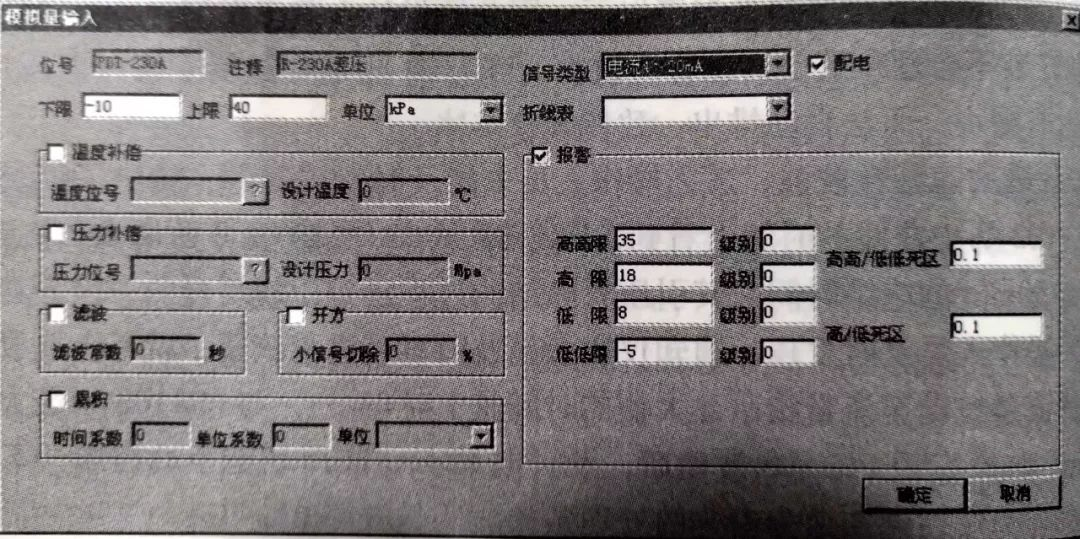

The process unit where the accident is located is the electrolytic repolarization tank A tank. The number of liquid phase differential pressure transmitter in tank A of electrolytic repolarization tank is PDI-SA-230A. The differential pressure transmitter is mainly used to measure the liquid phase pressure difference between the cathode chamber and the anode chamber of the electrolytic cell, to ensure that the liquid phase pressure difference is controlled within the range of 10-15kPa, so as to avoid the vibration of the ionic membrane caused by the large pressure difference, which will affect the The service life of the ion membrane.

Figure 1 Transmitter range setting screen

Accident process and handling process

(1) Operation before the accident

Before the accident, the device ran smoothly and normally, without any alarm information of abnormal conditions.

(2) A detailed description of the accident phenomenon

From 10:150 to 12:21 on January 10, 2008, the measurement data of the liquid-phase differential pressure transmitter in tank A of the electrolytic repolarization tank suddenly increased from 12kPa to more than 35kPa, exceeding the high and high limit alarm value (35kPa), DCS interlocking action, A slot tripped, the whole set of equipment was shut down.

(3) Scope of influence

Accidental shutdown of the electrolyzer can easily cause damage to the ion membrane and affect the stability of the upstream and downstream processes. The direct economic loss is about 30,000 yuan, and the indirect economic loss is about 50,000 yuan.

(4) Instrument and system processing process

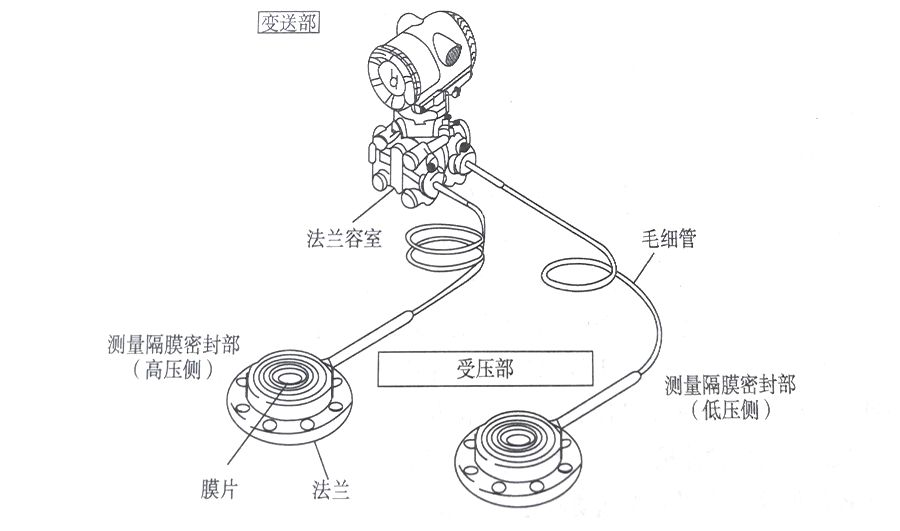

After the accident, the instrument personnel went to the site for inspection, disassembled and inspected the differential pressure transmitter, and found that a small hole had been burned in the PTFE anti-corrosion isolation diaphragm and sensing diaphragm on the low-pressure side, and the silicone oil in the capillary on the low-pressure side had leaked out. Can't transmit pressure.

The instrument personnel removed the faulty instrument, replaced a Microcyber differential pressure transmitter, and put it into operation after passing the calibration.

(5) The nature of the accident

Instrument equipment accident.

Accident Cause Analysis

(1) Direct cause analysis

The strength and insulation of the measuring diaphragm are insufficient, and it is damaged after being burned by high current, resulting in leakage of silicone oil and distortion of the measurement.

(2) Analysis of indirect causes

The electrolytic repolarization cell is a high-current electrolytic cell. The current is as high as 9kA at full load. Once the metal measuring diaphragm of the instrument is in direct contact with the medium, an electrochemical reaction will occur, and the metal measuring diaphragm will be corroded and broken down in a very short time. , causing internal silicone oil leakage.

Precautions

(1) Experience and lessons

This accident is mainly due to the fact that the instrument design and installation only considered the corrosion damage to the transmitter diaphragm by the electrochemical reaction, but did not consider the damage to the instrument caused by the high current of the electrolytic cell, and installed a relatively thin ordinary domestic PTFE isolation Anti-corrosion film.

(2) Technical measures. Strengthen the early management of instrumentation equipment, and instrument technicians participate in the selection of instrumentation equipment. And make analysis records according to the usage of the instrument, and find problems and improve them in time.

(3) Management measures. Instrument technicians and operators should conduct inspections in time to find problems in time. Regularly check the liquid-phase differential pressure measuring instrument, especially the integrity of the anti-corrosion isolation diaphragm. If abnormal conditions are found, replace them in time to avoid accidents caused by the same reasons.

(4) Organizational measures. Establish and improve the instrument management organization, regularly hold special meetings for instrument technicians to solve various problems in instrument equipment management. At the meeting, there are good experiences that can be promoted to each other and learn from each other's strengths.