Analysis of the common faults and solutions of temperature transmitters

Temperature transmitter technology has been very mature, very common in various factories, transmitters are often used in conjunction with a number of instruments, often in the process of supporting the use of some minor failures. The more common faults and solutions are as follows.

First, the measured medium temperature increases or decreases when the transmitter output does not change, this situation is mostly a temperature transmitter sealing problems, may be due to the transmitter is not sealed or in the welding time accidentally welded a small hole in the sensor, this situation generally need to replace the transmitter shell to solve.

Second, the output signal is not stable, this reason is the temperature source ability of the reason, the temperature source ability is an unstable temperature, if the instrument display is not stable, it is the instrument's anti-interference ability is not strong reason.

Third, the transmitter output error is large, this situation is more reasons, may be the choice of transmitter resistance wire is not the right lead to the range error, can also be the transmitter is not calibrated at the time of factory.

Troubleshooting:

1、Because the transmitter of the three valve group leakage or blockage caused by the error.

2、The zero position of the transmitter is high (or low), resulting in static and differential pressure value is large (or small), so that the calculated gas volume than the actual gas volume is large (or small).

3、The accuracy level of the transmitter and range range selection is not correct, or not in accordance with GB/T18603-2001 "natural gas metering system technical requirements" requirements for the selection of measurement of additional errors.

Solution to the error:

1、Regularly on the transmitter for sewage leakage inspection.

2、Regularly check the transmitter back to zero, found that there is anomaly or overdifference, should be promptly calibrated, due for verification.

3、Strictly in accordance with GB/T18603-2001 "natural gas metering system technical requirements" requirements for selection and installation.

4、Winter temperatures drop, especially the oilfield associated gas water content increases, easy to freeze and block, need to increase the number of sewage, to the transmitter with thermal insulation equipment (such as adding thermal insulation box and heat tape).

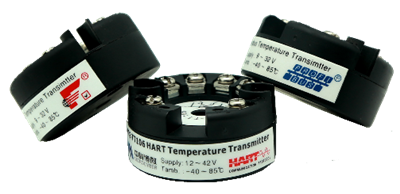

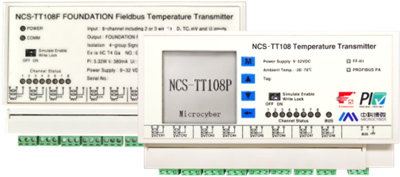

Microcyber 's Digital Temperature Transmitter

Head type: NCS-TT106H: HART protocol single channel temperature transmitter NCS-TT106P: PROFIBUS PA protocol single-channel temperature transmitter NCS-TT106F: FF H1 protocol single-channel temperature transmitter | |

Guide rail type: NCS-TT106H-R1: HART protocol single channel temperature transmitter NCS-TT106P-R1: PROFIBUS PA protocol single-channel temperature transmitter NCS-TT106F-R1: FF H1 protocol single-channel temperature transmitter | |

NCS-TT108P: PROFIBUS PA protocol multi-channel temperature transmitter NCS-TT106F-R1: FF H1 Protocol Multi-Channel Temperature Transmitter | |

Field type: NCS-TT105P: PROFIBUS PA protocol dual channel temperature transmitter NCS-TT105F: FF H1 Protocol Dual Channel Temperature Transmitter |