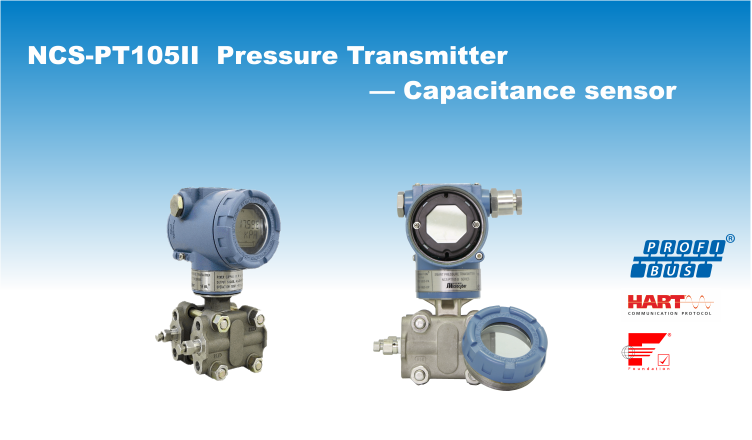

Pressure Transmitter Capacitance Sensor

- Microcyber

- China

- In Stock

- 500 Sets/Month

NCS-PT105II series pressure transmitter with capacitance sensor is available on FF H1, PROFIBUS PA and HART protocols. The transmitter has higher accuracy, better reliability and supports explosion proof.

1. Support the latest versions of FF H1, PROFIBUS PA and HART protocols

2. Pressure types include gauge pressure, absolute pressure, micro differential pressure, differential pressure and high static pressure

3. High precision: ±0.075% SPAN

4. Long term stability: ±0.1% URL within 12 months

5. FCG FF interoperability test certification, PNO interoperability test certification (PA profile 3.02), and FCG HART interoperability test certification (HART 7)

6. Explosion-proof (intrinsically safe, flameproof) certification

Pressure Transmitter--Capacitance Sensor

What is pressure transmitter?

NCS Series of Intelligent Transmitters are digital, intelligent, network-based, merged with advanced, reliable and stable sensor technology, to be designed as a new generation of Fieldbus Intelligent Transmitter.

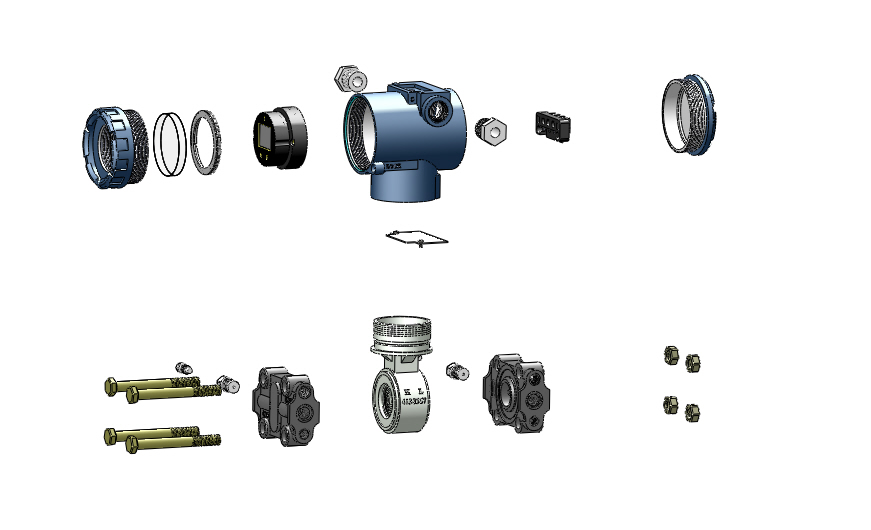

NCS-PT105Ⅱ series Smart Pressure Transmitter with advanced, mature, reliable 3151 capacitance sensors has been designed meticulously by combining advanced microprocessor technology and digital capacitance measurement technology. The powerful functions and high-speed computing capability of the microprocessor make it have excellent qualifications such as smart, high precision, high reliability, stable zero and so on. Its LCD can display many physical parameters (e.g. pressure, temperature, current and so on). It can realize the functions such as zero adjustment, range settings by key-press operation, and it is easy for field testing.

SEE VIDEO KNOW PERSSURE TRANSMITTER

According to the type of measurable pressure:

NCS-PT105ⅡSG: Gauge Pressure Transmitter

NCS-PT105ⅡSA: Absolute Pressure Transmitter

NCS-PT105ⅡSD: Differential Pressure Transmitter

NCS-PT105ⅡSH: Differential Pressure Transmitter For High Static Pressure

According to the protocol:

NCS-PT105ⅡF: FF H1

NCS-PT105ⅡP: PROFIBUS PA

As a transitional communication protocol in fuildbus, HART protocol achieves digital transmission on the existing analog transmission lines, and is coMpatible with existing analog signal control system. Either FF H1or PROFIBUS PA is a new generation of digital communication protocol, used in field connection, and linking field devices. International Standard IEC61158-2 is used in physical layer. Therefore, either FF H1or PROFIBUS PA is fieldbus actually.

As following, Smart Transmitter with HART protocol is named as HART Smart Transmitter; Smart Transmitter with FF H1 protocol is named as FF Smart Transmitter; Smart Transmitter with PROFIBUS PA protocol is named as PA Smart Transmitter, All of these (Transmitters with the three types of fieldbus protocol) are named as Smart Pressure Transmitters or Smart Transmitters. In addition, HART Smart Transmitter has passed explosion-proof certification from National Supervision and Inspection Center for Explosion Protection and Safety of Instrumentation (NEPSI).

Features

Excellent Performance

-- High precision: ±0.075% full range (20℃, within the range of 10:1)

-- Long-term stability: ±0.1% of the maximum range within 12 months

Flexibility

-- Pressure type selection (micro differential pressure, surface pressure, absolute pressure, differential pressure, high static differential pressure)

-- Parameters can be set by magnetic bar, hand operator and upper computer software

-- High range ratio (100:1)

Reliability

-- Self-detection function (sensor, memory, communication)

-- Automatic compensation function (ambient temperature compensation, sensor input linearization)

-- Software and hardware fault alarm function

-- Configuration protection: EEPROM write protection function

High Pressure Temperature Sensor's Parameter:

Measure Object: Liquid, Gas, Stream

Power:

9~32V DC(FF,PA)

9~32v DC (FF, PA Explosion-Proof Instrument)

11.9~42 V DC (HART)

11.9~30 V DC (Hart Explosion-Proof Instrument)

Output:

Analog: 2 Wire 4~20ma

Digital: HART, FF AND PA Signal

Load Resistant:

0~1500ohm (Common)

250~550ohm (With Hart)

Insulation:

Input And Output Insulating Voltage: 500vrms (707vdc)

Display:

Optional 6 Bits Digital Number Or 5 Bits Characters LCD Display

Temperature Scale:

Work Temperature: -40 ~ 85℃ (No Display)

-30 ~ 70℃ (Display)

-30 ~ 60℃ (Explosion-Proof)

Store Temperature: -40 ~ 100℃ (No Display)

-40 ~ 85℃ (Display)

Allowed Media Temperature Measured:

-40 ℃~ 110 ℃ (Type Name Include ‘IC‘)

-40 ℃~ 149 ℃ (Silicone Oil)

-40 ℃~ 204 ℃ (Sylthlem800)

-18 ℃~ 204 ℃ (Inert Liquid)

-40 ℃~ 104 ℃ (Others)

Humidity Scale: 5%~100%Rh

Start Time: ≤ 5 Seconds

Refresh Time: 0.2 Seconds

Dump Adjusting: Time Constant 0~15 Seconds

Change Of Cavity:< 0.16 Cm3

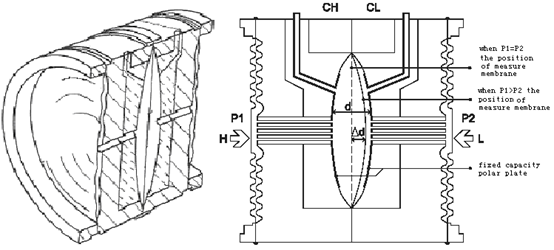

Introduction for Working Principle(How does a 4 20ma pressure transducer work?)

The widely used 3151 capacitive pressure sensors, which were developed by Rosemount initially in USA, have been produced on a large scale in China. The core of its sensor is differential capacitive membrane, as picture shows. There are two measurement capacitances CH and CL distributed in differential capacitive membrane. The two measurement capacitances are almost equal to two plate capacitances because of their mechanical structure. The two measurement capacitances share one polar plate, which is a measure membrane in the center. And the other polar plate is fixed on the two sides. When the pressures of two sides are equal, the measure membrane is in the center, the capacitances of two sides are equal too. But when the pressure of high pressure side is higher than that of low pressure side, the guide pressure liquid filled in the membrane guides the differential pressure, so that the measure membrane moves to low pressure side. As a result, the capacitance of high pressure side is lower than that of the low pressure side.

Sensor Capacitance Membrane

Differential Pressure Sensor's Structure

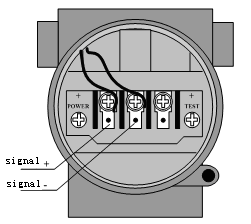

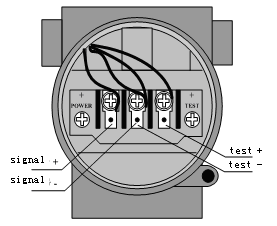

Pressure Transducer Wiring Diagram

The power and signal of Smart Transmitter are sharing one pair of cables (Bus Cable). The ordinary cables can be selected by HART smart transmitter, but FF, PA Smart Transmitter is suggested to use specific Fieldbus cable the IEC61158-2 recommended. The terminal is at the rear cover, the terminal wiring board could be seen after screwing the rear cover (indicated “FIELD TERMINAL”).

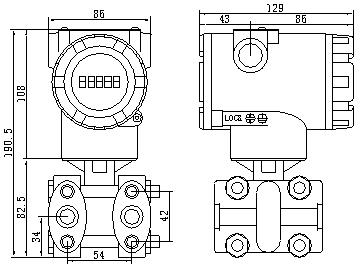

Dimension

Smart Transmitters Size shown as:

How To Choose NCS-PT105II Pressure Transmitter (Capacitance Sensor)?

Model | Name | |||||||||||||||

NCS-PT105ⅡSR | Differential Pressure Transmitter | |||||||||||||||

NCS-PT105ⅡSG | Gauge Pressure Transmitter | |||||||||||||||

NCS-PT105ⅡSA | Absolute Pressure Transmitter | |||||||||||||||

NCS-PT105ⅡSD | Differential Pressure Transmitter | |||||||||||||||

NCS-PT105ⅡSH | Differential Pressure Transmitter For High Static Pressure | |||||||||||||||

Code Name | Range (Kpa) | The Lower Limit Range (Kpa) | Limit the scope of(Kpa) | |||||||||||||

SR | SG | SA | SD | SH | ||||||||||||

2 | 0.03~1.5 | -1.5 | / | / | / | / | 1.5 | |||||||||

3 | 0.075~7.5 | / | -7.5 | / | -7.5 | / | 7.5 | |||||||||

4 | 0.374~37.4 | / | -37.4 | 0 | -37.4 | -37.4 | 37.4 | |||||||||

5 | 1.86~186.8 | / | -98 | 0 | -186.8 | -186.8 | 186.8 | |||||||||

6 | 6.9~690 | / | -98 | 0 | -690 | -690 | 690 | |||||||||

7 | 20.68~2068 | / | -98 | 0 | -2068 | -2068 | 2068 | |||||||||

8 | 68.9~6890 | / | -98 | 0 | -6890 | / | 6890 | |||||||||

9 | 206.8~20680 | / | -98 | / | / | / | 20680 | |||||||||

0 | 413.7~41370 | / | -98 | / | / | / | 41370 | |||||||||

Code Name | Communication Protocol | |||||||||||||||

H | HART Protocol | |||||||||||||||

P | PA Protocol | |||||||||||||||

F | FF Protocol | |||||||||||||||

Code Name | Structural Materials (Filling Liquid: Silicone Oil) | |||||||||||||||

Flanges, Joints, Drain/Exhaust Valves | Isolation Diaphragm | |||||||||||||||

22 | 316 Stainless Steel | 316LStainless Steel | ||||||||||||||

23 | 316 Stainless Steel | Hastelloy C | ||||||||||||||

24 | 316 Stainless Steel | Monel Alloy | ||||||||||||||

25 | 316 Stainless Steel | Tantalum | ||||||||||||||

32 | 304 Stainless Steel | 316LStainless Steel | ||||||||||||||

33 | 304 Stainless Steel | Hastelloy C | ||||||||||||||

34 | 304 Stainless Steel | Monel Alloy | ||||||||||||||

35 | 304 Stainless Steel | Tantalum | ||||||||||||||

Code Name | Parts | |||||||||||||||

M5 | LCD Liquid crystal display (LCD) | |||||||||||||||

IC | Ex ia IIC T4 Ga | |||||||||||||||

DC | Ex d IIC T4 Ga | |||||||||||||||

DA | Ex d IIC T6 Ga | |||||||||||||||

C60 | T Joint | |||||||||||||||

T2 | Three Valve Group (Stainless Steel) | |||||||||||||||

B1 | Pipe Bending Bracket (2"Pipe) | |||||||||||||||

B2 | Disc Bending Bracket | |||||||||||||||

B3 | Tube Mounting Flat Bracket(2"Pipe) | |||||||||||||||

D1 | Flanged Side Vent/Drain Valve At Upper Part | |||||||||||||||

D2 | Flanged Side Exhaust/Drain Valve At Lower Part | |||||||||||||||

NCS-PT105ⅡSG 4 H 22 C60M5 B1——Selection of the Sample | ||||||||||||||||

FAQ

Q: Which one is the most popular model?

A: NCS-PT105ⅡSG and NCS-PT105ⅡSD.

Q: How to install NCS-PT105II Pressure Transmitter (Capacitance Sensor) ?

A: There are three ways to install NCS-PT105II Pressure Transmitter (Capacitance Sensor): installation of pipe mounting flat bracket, installation of pipe mounting angle bracket and installation of plat mounting angle bracket.

Q: Can I get a free electronic manual?

A: Yes, if you want it, please contact us.

Q: Can you provided OEM service?

A: Yes, we can, such as communication board, we can also provided fieldbus development toolkit for pressure transducer.

HOT PRODUCTS